Service Details

TERM AND CONDITIONS

PURPOSE

REFERENCES

- API Standard 510:2022 Errata 1:2023, Pressure Vessel Inspection Code:In-service Inspection, Rating, Repair and Alteration.

- API Standard 570:2024, Piping Inspection Code:In-service Inspection, Rating, Repair and Alteration of Piping Systems.

- API Standard 650:2020 Errata 1:2021, Welded Tanks for Oil Storage.

- API Standard 653:2014 Addendum 3:2023, Tank Inspection, Repair, Alteration and Reconstruction.

- API Recommended Practice 571:2020, Damage Mechanisms Affecting Fixed Equipment in the Refining Industry.

- API Recommended Pratice 572:2023, Inspection of Pressure Vessels.

- API Recommended Pratice 574:2024, Inspection Practices for Piping System Components.

- API Recommended Practice 575:2020, Inspection of Atmospheric and Low-Pressure Storage Tanks.

- API Recommended Pratice 576:2024 Inspection of Pressure-relieving Devices.

- API Recommended Pratice 577:2020, Welding Processes, Inspection and Metallurgy.

- API Recommended Pratice 578:2023, Material Verification Program for New and Existing Assets.

- API Recommended Pratice 579-1/ASME FFS-1:2021, Fitness-For-Service.

- API Recommended Pratice 580:2023, Risk-based Inspection.

- API Recommended Pratice 651:2014, Cathodic Protection of Aboveground Petroleum Storage Tanks.

- API Recommended Pratice 652:2020, Lining of Aboveground Petroleum Storage Tank Bottoms.

- ASME Section V:2025, Nondestructive Examination.

- ASME Section VIII Division 1:2025 Rules for Construction of Pressure Vessels.

- ASME Section IX:2025, Qualification Standard for Welding Procedures, Welders and Welding Operators.

- ASME B16.5:2025, Pipe Flanges and Flanged Fittings:NPS 1/2 Through NPS 24 Metric/Inch Standard.

- ASME B31.3:2024, Process Piping.

- ASME PCC-2:2022, Repair of Pressure Equipment and Piping.

- RSA-QM-1001 Revision 1, Quality Manual- RSA Certification Body Quality Management System.

SCOPE

- The IPCS is created to meet the minimum qualification and certification requirements for Plant Inspectors in accordance with the API documents listed in the references.

- Certification provides an attestation of general competence, but does not authorize the individual to operate; authorization remains the employer’s responsibility.

- Certified personnel may still require additional specialized knowledge related to employer-specific equipment, procedures, materials, or products.

- Employers must issue written authorization based on a quality procedure that includes job-specific training and examinations to verify knowledge of relevant codes, standards, procedures, equipment, and acceptance criteria.

- The Levels of Plant Inspectors covered by this IPCS are listed in Level of Certification, following the applicable codes, standards, specifications, and regulations.

Certification

Level of Certification

Assistant Plant Inspector - Assistant Plant Inspector must have a broad knowledge and skills relating to visual inspection and equipment to be inspected as described in API 572, API 574 or API 575.

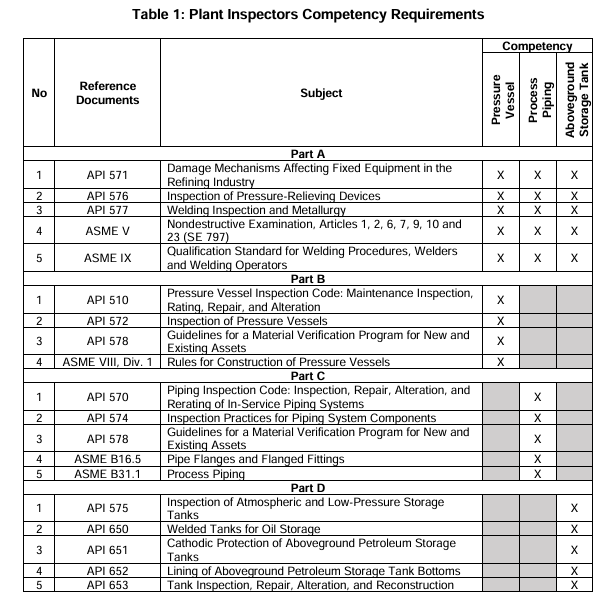

Plant Inspector - Pressure Vessel Inspectors must be skilled in the maintenance, inspection, repair, and alteration of pressure vessels as per API 510, applying relevant rules from Table 1, Parts A and B. Process Piping Inspectors should have strong expertise in maintaining, inspecting, altering, and repairing in-service metallic piping systems following API 570, and be able to apply standards from Table 1, Parts A and C. Aboveground Storage Tank Inspectors must be knowledgeable in the inspection, repair, alteration, and reconstruction of tanks according to API 653, and capable of applying rules and practices from Table 1, Parts A and D.

Specialist Plant Inspector - Specialist Plant Inspectors in Damage Mechanism must have a broad knowledge and the necessary skills to describe and analyse each flaw and damage identified by Plant Inspectors, in accordance with API 571. In the area of Risk Based Inspection, they must be proficient in developing, implementing, and maintaining a comprehensive Risk Based Inspection (RBI) program as outlined in API 580. Furthermore, for Fitness for Service, these inspectors must be capable of assessing the structural integrity of equipment with known flaws or damage to ensure safe continued operation and to support maintenance optimization, as described in API 579-1.